Lime production: traditional techniques in Patarra, Costa Rica

Practical Action

• The amount of waste produced by the lumber industry in the area is expected to

decline in the next five years, making lime burning increasingly dependent on timber.

• Working conditions for employees in the whole process are poor.

• The tendency to leave quicklime exposed to air for a period before hydrating it results

in some undesirable premature slaking.

• The system does attempt to separate out the 4 to 8% silicate-based impurities in the

lime which come from using an impure limestone.

The overall result of these problems is that the quality of the product is low in terms of both

the available lime content and the fineness. It is suitable only for agricultural purposes, and

only a low percentage is used in the construction industry, which, in any case is decreasing

its use of lime in the area. Marketing studies have shown that construction and other

industrial activities could increase their consumption of lime if the quality standards

improved without excessive increase in cost. The largest difficulty in obtaining a standard

quality for the lime is inadequate hydration.

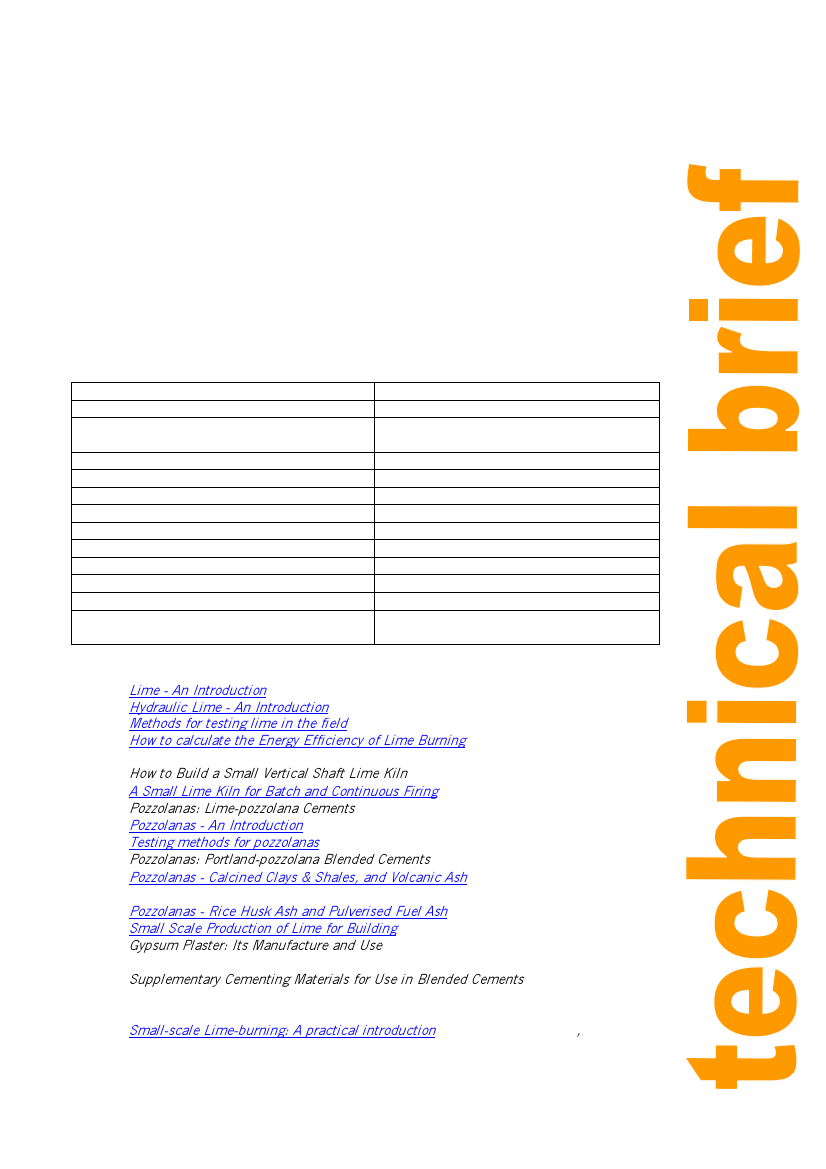

Information at a glance

Type of kiln

Capital costs

Mode of production

Running costs

Type and quality of limestone

Fuel efficiency

Conversion rate CaCO3 TO CaO

Hydration

Sieving/classification

Milling

Quality of lime produced

Principal market

Number of persons employed (including

quarrying)

Traditional cylinder, open topped

Very low

One batch per 8 days, average of 15

batches per year

Low

Marble approx 80% CaCO3

16%

96%

Manual

Manual

Electric hammer mill

Low (average 45% available lime)

Agriculture

3 full time and 8 casuals

References and further reading

• Lime - An Introduction Practical Action Technical Brief

• Hydraulic Lime - An Introduction Practical Action Technical Brief

• Methods for testing lime in the field Practical Action Technical Brief

• How to calculate the Energy Efficiency of Lime Burning Practical Action Technical

Brief

• How to Build a Small Vertical Shaft Lime Kiln Practical Action Technical Brief

• A Small Lime Kiln for Batch and Continuous Firing Practical Action Technical Brief

• Pozzolanas: Lime-pozzolana Cements Practical Action Technical Brief

• Pozzolanas - An Introduction Practical Action Technical Brief

• Testing methods for pozzolanas Practical Action Technical Brief

• Pozzolanas: Portland-pozzolana Blended Cements Practical Action Technical Brief

• Pozzolanas - Calcined Clays & Shales, and Volcanic Ash Practical Action Technical

Brief

• Pozzolanas - Rice Husk Ash and Pulverised Fuel Ash Practical Action Technical Brief

• Small Scale Production of Lime for Building John Spiropoulos, GTZ,1985

• Gypsum Plaster: Its Manufacture and Use, A. Coburn, E. Dudley and R.Spence,

Practical Action Publishing, 1989 (now out of print).

• Supplementary Cementing Materials for Use in Blended Cements, R.J. Detwiler, J.I.

Bhatty, S. Bhattacharja, Research and Development Bulletin RD112T, Portland

Cement Association, Skokie, Illinois, USA, 1996

• Small-scale Lime-burning: A practical introduction M. Wingate and others, Practical

Action Publishing, 1985.

4